What To Know About Becoming A Diesel Mechanic

Introduction and Outline

When supply chains hum, transit routes keep schedules, and farms harvest on time, diesel mechanics are quietly making it happen. This field rewards curiosity, grit, and precision, bringing together the satisfaction of tangible results with the challenge of modern electronics and emissions systems. It is a career with staying power; even as technology evolves, heavy-duty machines still need skilled hands and clear minds to diagnose and repair what software cannot. If you are considering this path, understanding the day-to-day work, training routes, and growth potential will help you decide where to start and how far you can go.

Here is the outline for this guide, designed to walk you from exploration to action without fluff:

– The Work: Systems, tasks, environments, and specializations you will encounter in the field.

– Training and Skills: Pathways into the trade, essential abilities, and recognized credentials.

– Job Market and Pay: Demand drivers, salary ranges, schedules, and career ladders.

– Tools, Safety, and Workflows: How technology shapes the job and how to protect your body and time.

– Next Steps and Conclusion: Practical actions to get hired, build momentum, and stay current.

Along the way, you will find comparisons with related trades, examples pulled from real-world scenarios, and practical tips you can use immediately. Expect a frank look at the physical demands, the problem-solving highs, and the realities of shop life—like why clean electrical connectors can save a day’s work, or how a single overlooked torque spec can undo a job. By the time you finish, you will have a clear map of the landscape and a checklist for your first or next move.

The Work: Systems, Tasks, and Specializations

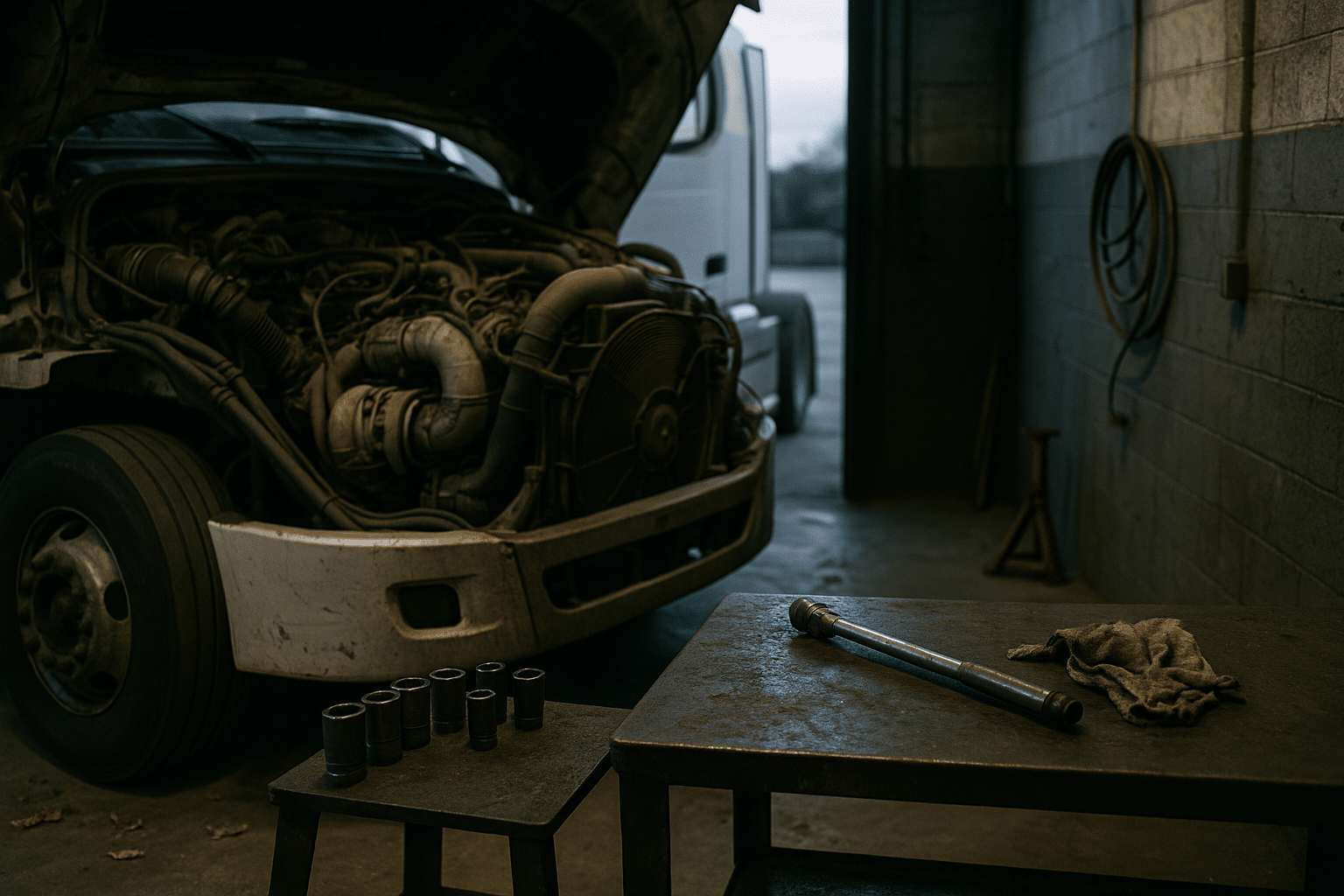

Diesel mechanics repair and maintain engines and the complex systems around them. That includes fuel delivery, turbocharging, cooling, lubrication, aftertreatment, braking, steering, and chassis. A typical day might start with a scheduled service—filters, fluids, and inspections—and shift quickly to a drivability complaint that requires scanning fault codes, following wiring diagrams, pressure-testing a fuel rail, or performing a smoke test to track down an elusive air leak. While the stereotype is heavy wrenches and grease, today’s workflow blends laptop diagnostics with mechanical precision.

Compared with light automotive work, diesel tasks often involve higher torque, larger fasteners, and heavier components that require hoists or lift tables. Safety practices are different too: high-pressure fuel systems and compressed air demand strict procedures. And because many fleets run around the clock, you may see night shifts, early starts, or mobile service calls. The upside is variety—few days play out the same way—and the sense of accomplishment when a sidelined rig roars back to life.

Many mechanics develop a niche that fits their interests and environment. Common specializations include:

– On-highway trucks and buses: Focused on powertrains, emissions systems, and preventive maintenance cycles.

– Off-highway and construction equipment: Emphasis on hydraulics, undercarriage, and dusty, rugged conditions.

– Marine and stationary engines: Priority on cooling systems, corrosion control, and steady-load reliability.

– Generator and power systems: Centered on fuel quality, load testing, and uptime metrics for critical facilities.

Each specialization brings different challenges. For example, an on-highway focus may require deep familiarity with exhaust aftertreatment and frequent sensor diagnostics, while heavy equipment work leans into hydraulic schematics and contamination control. If you enjoy troubleshooting complex electrical issues, fleet environments with telematics can be a great fit. If you prefer mechanical assemblies and fieldwork, off-highway roles may be more satisfying. In short, the trade offers room to tailor your career without leaving the core skill set behind.

Training, Skills, and Recognized Credentials

There are multiple pathways into diesel repair. Some enter straight from high school as shop helpers or apprentices and learn on the job. Others complete vocational programs that accelerate exposure to engines, brakes, electrical systems, HVAC, and safety fundamentals. Still others pivot from related trades—welding, machining, or light automotive—bringing transferable skills that shorten the learning curve. Regardless of starting point, the essentials stay consistent: show up on time, ask good questions, master the basics, and build trust through careful, documented work.

Core competencies that pay off quickly include:

– Electrical fundamentals: Reading diagrams, using a multimeter, and understanding voltage drop.

– Mechanical precision: Torque, cleanliness, assembly order, and thread repair.

– Diagnostics discipline: Confirming the complaint, testing before guessing, and verifying the fix.

– Communication: Clear notes, honest estimates, and helpful explanations for non-technical colleagues.

– Safety: Lockout/tagout, lifting best practices, and awareness around high-pressure fluids and hot components.

Formal training can shorten time to proficiency, but hands-on repetition cements skill. Many shops support continuing education, offering short courses on topics like common rail fuel systems, turbo diagnostics, aftertreatment service, vibration analysis, and hydraulic contamination control. Professional credentials also signal readiness to employers. Look for industry-recognized certifications that cover diesel engines, brakes, preventative maintenance inspection, and electrical/electronic systems. These credentials test theory and practice and can lead to higher pay tiers, shift preferences, or team lead roles.

Tooling is another aspect of training. Start with quality hand tools and gradually add specialty items as your workload demands them—think torque wrenches, test leads, back probes, a reliable multimeter, and safe lifting aids. Many employers provide larger shop equipment and scan tools, but having your own essential kit builds speed and independence. Finally, cultivate a habit of post-repair reflection: what diagnostics worked, what steps were unnecessary, and what notes will help the next tech—or future you—solve a similar problem faster.

Job Market, Pay, and Career Advancement

Heavy-duty transport, construction, agriculture, and public services all depend on diesel power, and that broad footprint supports steady demand for skilled mechanics. Official labor statistics consistently point to single-digit growth over the decade, with retirements and fleet expansion creating openings across urban and rural areas. Electrification and alternative fuels are gaining ground in some segments, but diesel remains dominant in heavy-duty applications due to energy density, range, and refueling infrastructure. That means technicians who understand both traditional systems and newer technologies are well positioned.

Compensation varies widely by region, sector, and shift. A practical way to think about pay is by experience and responsibility:

– Entry-level: Often in the low to mid forties annually in many regions, with growth tied to productivity and added responsibilities.

– Mid-career: Frequently climbs into the sixties and seventies, especially with strong diagnostics or mobile service duties; overtime can lift totals further.

– Senior and supervisory: Team leads, foremen, and field specialists may see earnings beyond these ranges, reflecting leadership, scheduling, and customer contact.

Scheduling affects both income and lifestyle. Second and third shifts can carry differentials, and weekend coverage often brings overtime. Mobile roles may add callout pay and travel stipends but trade that for unpredictable hours and weather exposure. Benefits—health coverage, retirement contributions, paid training, and tool allowances—add meaningful value, so compare the full package, not just the hourly rate.

Career pathways are flexible. Many mechanics move from general service to diagnostics specialist, then into team lead or shop foreman. Others pivot to parts management, warranty analysis, service writing, or technical training. A few branch into equipment sales or start independent mobile repair businesses once they have a client base. The common thread is documented competence and reliability—keep a portfolio of repair orders, photos, and quantifiable outcomes, like reduced comebacks or improved inspection pass rates, to support your next step.

Conclusion and Next Steps for Aspiring Diesel Mechanics

Getting hired in this field is a mix of readiness and reputation. Start by visiting shops—fleet, independent, and dealer-affiliated—to see how they operate and what they value. Bring a concise resume that highlights hands-on projects, safety training, and any relevant coursework. If your experience is light, a short skills section can demonstrate initiative: electrical basics, torque procedure, thread repair, cooling system service, or brake inspection. A short, honest cover note helps too; explain why the trade fits you and what you hope to master in the first year.

Practical steps to build momentum:

– Shadow a working technician for a day to confirm your interest and observe workflow.

– Enroll in an introductory diesel or electrical course to anchor your fundamentals.

– Build a modest tool kit focused on reliability and safety, adding specialty tools as needed.

– Start a repair log and photo portfolio, even for school or personal projects, to show process and results.

– Seek mentors; their shortcuts and checklists can save you from expensive mistakes.

Once you land a role, stack small wins. Arrive prepared, keep bays orderly, label parts, and write notes that someone else can follow. Before replacing a component, ask yourself what test proves it failed and what might have caused it. Verify the fix and record the numbers—pressures, voltages, temperatures—so your work tells a clear story. Over time, those habits compound into trust, which opens doors to advanced diagnostics, fieldwork, or leadership roles.

In closing, diesel mechanics keep essential industries moving, and the trade rewards those who blend careful thinking with steady hands. The work can be physically demanding and occasionally messy, but it offers tangible progress, wide-ranging opportunities, and the pride of putting critical machines back to work. If that mix sounds like you, start with the outline above, take the next concrete step this week, and build your career one accurate diagnosis at a time.