Explore Wall Panel Design Options

Introduction & Outline: Why Wall Panels Matter Today

Wall panels do more than dress a surface; they bring structure, purpose, and performance to rooms that need acoustics, durability, or visual character. In living areas, panels add rhythm and shadow that feel calm rather than cluttered. In kitchens and baths, moisture-tolerant options protect high-traffic zones and clean easily. Offices and studios benefit from panels that tame echo so conversations are clearer and video calls sound professional. Unlike a full remodel, panels can be added with limited disruption, targeted to problem walls, and selected to meet your exact goals—whether that’s a quick style lift or a serious performance upgrade.

Before we dive in, here’s the roadmap this article follows, so you can jump to what you need or read end to end for a complete plan:

– Materials and Types: A side-by-side look at wood, composites, PVC, gypsum, metal, stone veneer, acoustic assemblies, and what each excels at.

– Performance, Codes, and Installation: Fire ratings, moisture management, sound absorption, fastening systems, and step-by-step planning tips.

– Design Strategies and Room-by-Room Ideas: Height rules for wainscoting, slat spacing, color and pattern tactics, and lighting interplay.

– Budgets, Maintenance, and Sustainable Choices: Realistic cost ranges, what to maintain, lifespan considerations, and lower-impact options.

Think of panels as clothing for the architecture. Some are tailored, some are rugged, some are whisper-quiet, and some are all about texture. The trick is to pair the right fabric—medium-density fiberboard, real wood, resilient PVC, or non-combustible mineral boards—with the function of the space. By the end, you’ll have clear criteria to shop with confidence, a short list of finish ideas, and an installation plan you can execute yourself or hand to a contractor without ambiguity.

Materials and Types: Comparing What Goes on the Wall

Materials set the tone for both appearance and performance. Wood and wood-derived options are popular because they’re warm, easy to work, and endlessly finishable. Medium-density fiberboard (MDF) offers crisp profiles for shiplap, beadboard, and raised or flat panels at a reasonable cost; it machines cleanly but needs sealing at edges to resist swelling in damp areas. Plywood with a hardwood veneer brings authentic grain and better screw-holding than MDF, with weight and stability varying by grade. Solid wood panels provide the most natural character and the potential for refinishing, but they require attention to acclimation and seasonal movement.

Polymer and mineral-based panels occupy the durability and safety end of the spectrum. Rigid PVC and similar plastics shrug off splashes and humidity, making them suitable for laundry rooms, mudrooms, and utility spaces; expect minimal maintenance beyond occasional wiping. Gypsum-based and other mineral panels are non-combustible and often achieve a Class A surface flame rating, making them candidates where fire performance is a priority. Fiber cement and mineral composite boards resist impact and heat but are heavier and require carbide tools. Metal panels—aluminum or steel—create a crisp, contemporary look and are tough in commercial corridors or workshops; they can dent, but touch-ups are straightforward.

Specialty assemblies expand what panels can do. Acoustic slat systems pair wood or laminate slats with a felt backing; depending on spacing, air gap, and added insulation, absorption can range from modest diffusion to NRC values around 0.7–0.9 in targeted frequencies. Fabric-wrapped acoustic panels are light, modular, and effective for echoes, typically reaching NRC values from 0.7 upward when properly mounted. Insulated or foam-backed panels contribute noticeable thermal comfort in cold spots, adding roughly R-1 to R-3 depending on thickness. Textured 3D panels—ribs, waves, geometric tiles—offer dramatic shadows; they’re especially effective when raking daylight animates the surface.

How do you choose among them? Consider a quick scorecard:

– Moisture resistance: PVC and mineral boards lead; sealed plywood fares better than unsealed MDF.

– Fire: Mineral boards and metal are non-combustible; many decorative wood panels are acceptable in typical residential settings but verify local requirements.

– Acoustics: Slat/felt and fabric-wrapped assemblies excel; solid, reflective panels can be balanced with soft furnishings.

– Workability: MDF and plywood cut smoothly; fiber cement and metal need specialized blades and dust precautions.

– Finish options: Wood takes stain and oil beautifully; polymers rely on factory texture or compatible paints; mineral boards usually get paint or skim coats.

Thickness commonly ranges from 6 to 12 mm for decorative skins and 18 mm or more for structural or slatted elements. Weight varies widely—light fabric-wrapped panels might weigh under 1 lb/ft², while dense composite or stone veneer modules can exceed 3 lb/ft²—so align your fasteners and substrate accordingly.

Performance, Codes, and Installation: Getting It Right

Panels are more than a pretty face; they interact with sound, heat, and moisture. In open rooms with hard floors and minimal textiles, sound reflections can make a space feel fatiguing. Acoustic slats over felt, spaced consistently and installed over batt insulation, absorb mid to high frequencies and reduce reverberation, which shows up immediately in clearer speech and less “ring” on calls. If thermal comfort is the goal, foam-backed panels or an added continuous underlayment can reduce drafts along exterior walls; while thin layers won’t replace cavity insulation, the surface temperature lift can make seating areas feel noticeably cozier.

Codes and safety are about appropriateness and location. Many jurisdictions require Class A surface flame spread in corridors or shared spaces; mineral-based panels, gypsum, and metal typically comply, while decorative wood often lives comfortably in residential areas without special requirements. In wet zones, treat panels like you would tile: protect the substrate with an approved moisture barrier, seal seams, and avoid placing non-rated wood panels inside direct-spray shower areas. In kitchens, consider splatter height behind ranges and use heat-tolerant materials or a removable protector near high-heat appliances.

Installation starts with the wall. Check for flatness with a long straightedge; plane or float high and low spots so panels don’t telegraph unevenness. Locate studs—commonly 16 inches on center—and map them lightly in pencil. Dry-fit panels to plan seams and pattern alignment, especially for slats or geometric reliefs where continuity is part of the look. Allow expansion gaps at perimeters (often around 3 mm) and between modules if the manufacturer recommends it.

Fastening choices depend on material:

– Adhesive-only: Effective for lightweight panels on sound drywall; use a construction-grade adhesive compatible with the substrate.

– Nails or brads: Traditional for beadboard and shiplap; back it up with adhesive to reduce movement and fill holes for a clean finish.

– Hidden clips or cleats: Enable future removal, helpful for access panels or rental-friendly installs.

– Furring and air gaps: Improve acoustic performance and create space for wiring, but remember to extend outlets to the new surface plane with code-compliant spacers.

Finishing and health considerations matter. Seal cut edges on MDF and plywood; it improves paint uniformity and moisture resistance. Choose low-emission coatings to protect indoor air quality, and ventilate during application. For dense or abrasive materials, wear eye protection and a respirator rated for dust; some mineral boards generate fine silica dust when cut. Finally, work clean: vacuum as you go, protect floors, and label back-of-panel positions to speed reinstallation if you need to remove and adjust.

Design Strategies and Room-by-Room Ideas

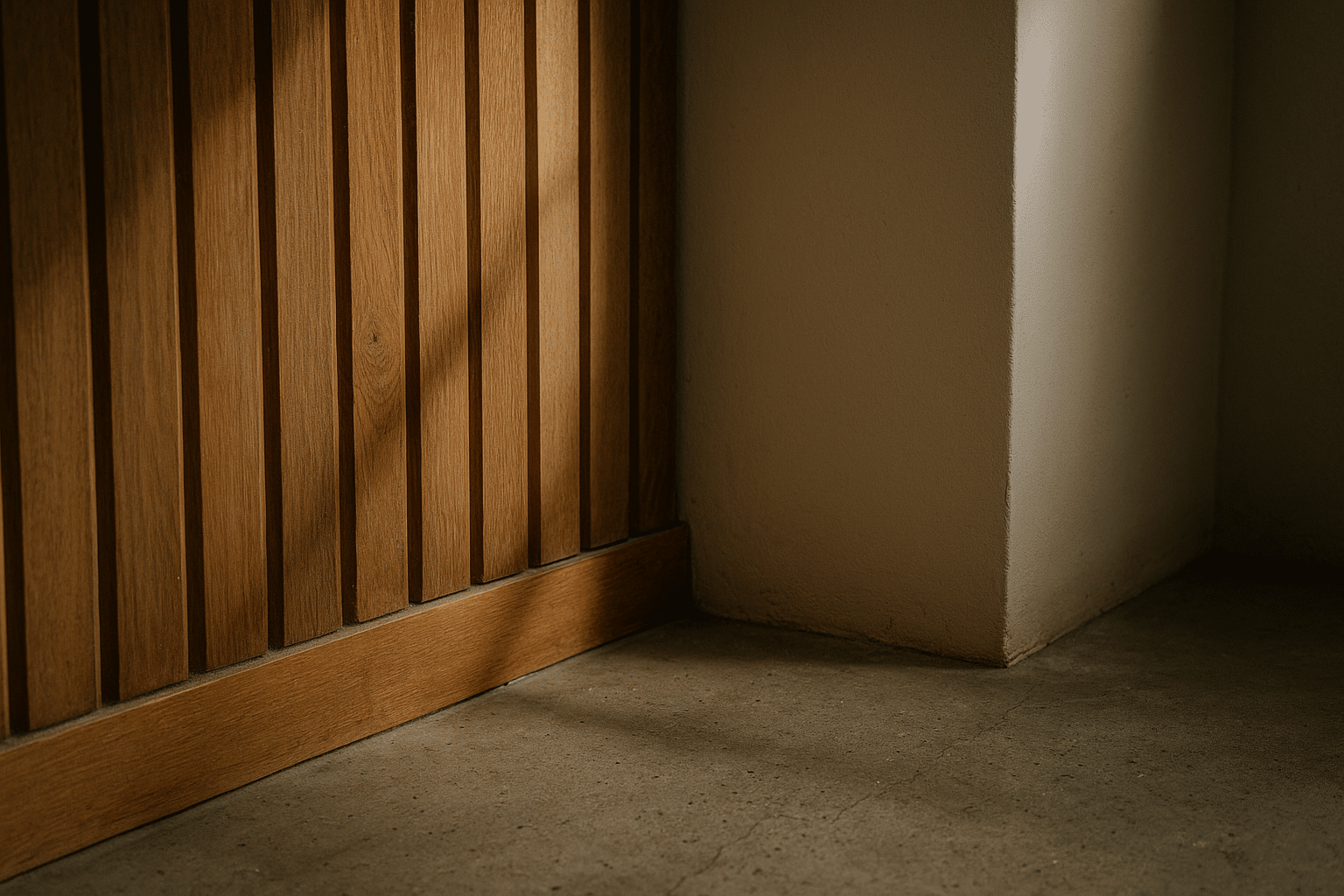

Design with panels is a dance between proportion, light, and texture. In small rooms, vertical lines—beadboard or narrow slats—pull the eye upward and make ceilings feel taller. In larger spaces, wider planks or grid panels introduce calm order, much like a tailored jacket that tidies a silhouette. Color shifts the mood dramatically: pale tones amplify daylight and show off subtle shadows, while deeper hues turn walls into a cozy backdrop for art and soft furnishings. Natural wood species add warmth and variation; even a single feature wall of oak, ash, or walnut-toned veneer can center a room without shouting.

Wainscoting guidelines are simple and effective. A common starting point is one-third of wall height—roughly 32–42 inches—but let adjacent elements weigh in. If your window sills or countertop backsplashes set a clear horizontal, align to them so the eye reads a cohesive line. Cap rails can be pencil-thin for modern spaces or more pronounced for traditional rooms; either way, ensure the transition to painted wall above is crisp and intentional.

Slat panels invite rhythm. Consistent spacing (often 13–25 mm) keeps the pattern from looking busy; set your spacing to harmonize with door casings and outlets so cuts don’t land awkwardly. Mounting slats over a dark felt backing increases depth, while matching the backing to the slat color quiets the contrast. A shallow reveal at corners adds a crafted touch and accommodates seasonal movement in wood-based slats.

Consider how panels interact with daylight. Raking morning light reveals texture delightfully on ribbed or fluted surfaces; a smooth painted panel reflects more gently and brightens a dim corridor. If you plan accent lighting, wash panels indirectly from above or below rather than spotlighting them; the softer the angle, the richer the shadows. Mirrors, art, and shelving read especially well against panels because the surface already provides a visual anchor.

Room-focused ideas to spark planning:

– Entry: Durable wainscot with hooks and a narrow ledge keeps daily clutter in check and walls scuff-free.

– Living room: A single paneled feature wall frames the sofa and improves clarity for conversation or streaming.

– Kitchen: Moisture-ready panels for the breakfast nook backsplash height add easy-clean function without tile.

– Bedroom: Calm slats or square grids behind the headboard set a restful tone and reduce early-morning echoes.

– Office or studio: Fabric-wrapped modules behind the desk or along side walls make calls clearer and recordings cleaner.

Budgets, Maintenance, and Sustainable Choices: Buying Guide and Conclusion

Costs vary by material, finish, and labor, so build a range and refine from there. As a broad orientation, decorative MDF or plywood panels often land around low-to-mid single digits per square foot for materials, rising with premium veneers and built-up mouldings. Moisture-tolerant polymers typically sit in the mid range, while acoustic slat assemblies, fabric-wrapped panels, metal, and stone veneer can move into double digits per square foot. Professional installation commonly adds a few to several dollars per square foot depending on prep, complexity, and region. A small feature wall might come together over a weekend with basic tools, while a full-height, mitered wrap with outlets and built-ins commands more time and skill.

Total cost of ownership matters as much as day-one price. Panels that are durable, easy to wipe, and repairable cost less over time. Wood and veneer can be refinished; a gentle sand and fresh coat can reset years of wear. PVC and mineral boards simply wash clean; avoid harsh abrasives that dull finishes. For acoustics, modular designs let you add or subtract units as needs change—handy if you reconfigure a room. Keep a few spare slats or tiles labeled and stored; color and grain vary by batch, and spares make seamless repairs possible.

If lower-impact choices are a priority, look at three big levers: material content, emissions, and lifespan. Panels made with recycled fibers or metals reduce demand for virgin resources, and responsibly sourced wood supports forest health. Low-emission adhesives and finishes help keep indoor air fresher during and after installation. Durability is the quiet sustainability win; a panel that lasts decades with occasional refinishing usually beats a faster-wearing option that needs frequent replacement. When you remove panels, consider reuse: slats can become shelving; cutoffs make drawer organizers; intact modules can refresh a hallway or closet.

Shopping checklist for clarity and confidence:

– Define the goal: acoustic comfort, moisture protection, visual texture, or a mix.

– Measure twice: mock up panel heights and spacing with painter’s tape.

– Verify performance: look for published fire classifications, acoustic data (NRC), or moisture suitability where relevant.

– Plan the substrate: flat, dry, and sound walls save time and yield crisp results.

– Choose finishes early: paint or stain colors interact with room light—test boards in place at different times of day.

– Budget the extras: trim, outlet extensions, adhesives, primers, and edge sealers add up.

Final takeaways: For homeowners, panels are a realistic way to add character and comfort without structural work. For renters, removable cleat systems and narrow feature walls offer impact that can come down later. For designers and facility managers, panels align aesthetics with measurable outcomes—acoustics, durability, cleanability—making spaces feel better and perform better. Start with the wall that bothers you most, pick a material that fits the job, and let proportion and light do the rest. Your walls don’t just stand there; with the right panels, they work for you.